Malolactic fermentation, often abbreviated as MLF, is a secondary fermentation process that occurs in wine production. This process is distinct from primary alcoholic fermentation, where sugar is converted into alcohol. In malolactic fermentation, the process involves the conversion of malic acid, present in grape must, into lactic acid. This malolactic conversion is facilitated by lactic acid bacteria, predominantly Oenococcus oeni.

Understanding the role and importance of malolactic fermentation is crucial for winemakers, as the process has a significant impact on the aroma, flavor, and texture of the final product. During MLF, certain components in the wine undergo a transformation that can decrease acidity, making the overall flavor profile rounder and more balanced. This process is crucial in the production of full-bodied red wines – such as Cabernet Sauvignon and Pinot Noir – and some white wines, like Chardonnay. By controlling the conditions of the wines that undergo malolactic fermentation, winemakers can ultimately influence the characteristics and quality of their wines.

Given the complex role of malolactic fermentation in wine production, it is essential to explore the factors that influence its progress, such as temperature, pH, and nutrient availability. This understanding allows winemakers to manage the process effectively, ensuring a balanced final product that meets the desired quality and sensory attributes.

Understanding Malolactic Fermentation

How does Malolactic fermentation start

Malolactic fermentation, also known as MLF, is a fascinating process that starts with the introduction of lactic acid bacteria into the wine. These bacteria, typically of the Oenococcus oeni species, initiate the conversion of harsh malic acid into softer lactic acid, thus reducing the overall acidity of the wine. The start of malolactic fermentation is often triggered by environmental factors such as temperature and pH levels, as well as by the presence of residual sugars or nutrients in the wine. Once spontaneous malolactic fermentation is initiated, MLF can take several weeks to complete and is essential for developing complex flavors and aromas in many types of wine.

Acetic acid can be formed as a side product in wines that undergo malolactic fermentation as well as alcoholic fermentation. It is an unwanted side product as it alters the wines taste. The formation of acetic acid is generally observed during alcoholic fermentation if the wine is exposed to oxygen.

Purpose and Benefits

Malolactic fermentation (MLF) is a secondary fermentation process in wine production, mainly used in red wines and some white wines. It converts malic acid, which is naturally present in grape must, into lactic acid and carbon dioxide. This process imparts several benefits to the wine, such as:

- Softer acidity: By converting the sharper and more tart malic acid into smoother and milder lactic acid, MLF produces a more balanced wine with a pleasant mouthfeel.

- Enhanced flavor: MLF can introduce complex flavors and aromas, such as buttery, nutty, and fruity notes, which add depth and dimension to the wine.

- Improved stability: Reducing malic acid levels minimizes the risk of spoilage and ensures that the wine remains stable during aging and storage.

Chemical Process Involved

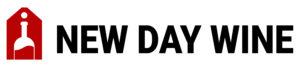

The process of malolactic fermentation is primarily driven by lactic acid bacteria, mainly from the Oenococcus oeni species. These bacteria convert the malic acid (C4H6O5) into lactic acid (C3H6O3) through decarboxylation, which involves the removal of a carbon dioxide molecule (CO2). The chemical reaction can be represented as follows:

Malic acid → Lactic acid + CO2

This is in contrast to alcoholic fermentation where sugar molecules are concerted into alcohol and carbon dioxide. Other compounds like glycerol, acetaldehyde or acetic acid appear in the metabolism.

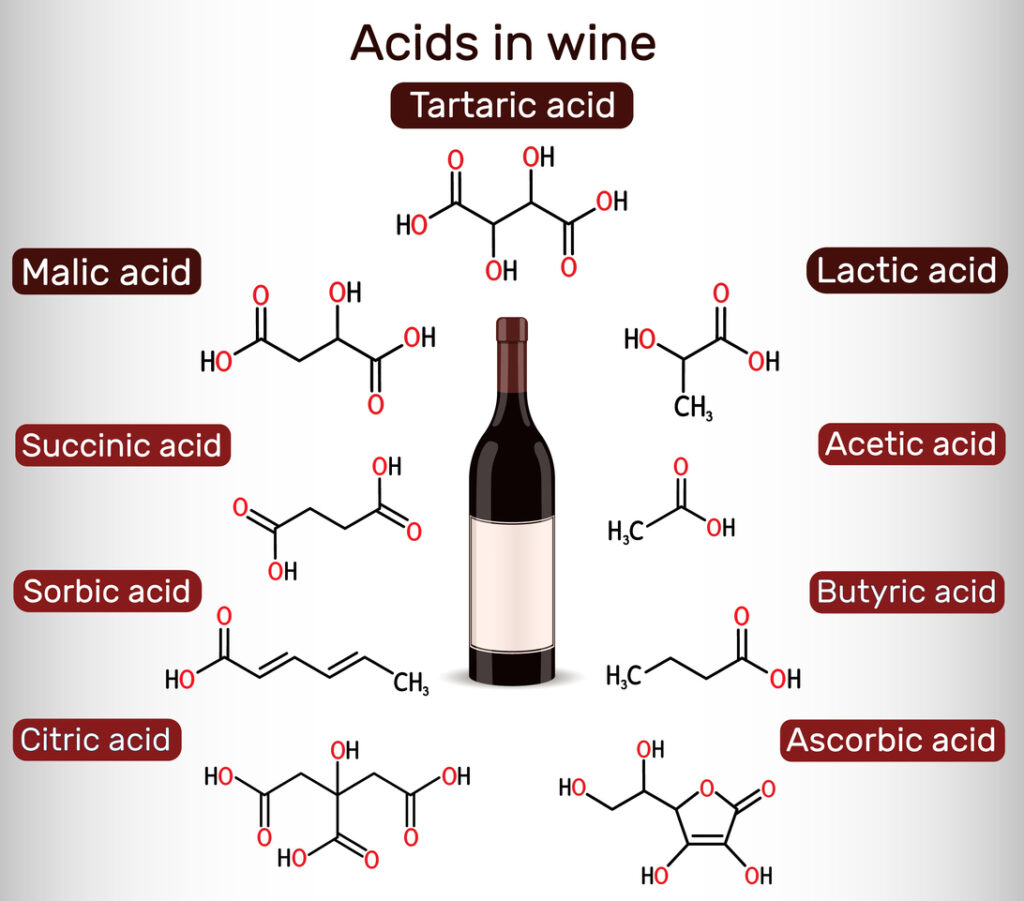

Temperature and pH conditions play a crucial role in the success of malolactic fermentation. The ideal temperature range for MLF is between 15-25°C (59-77°F), and the optimal pH level is around 3.2-3.8. It is essential to monitor and control these factors to ensure the proper conversion of malic acid into lactic acid and prevent the growth of undesirable microorganisms.

In summary, malolactic fermentation is a critical step in wine production that provides numerous benefits, including softer acidity, enhanced flavor, and improved stability. The process yeast fermentation is facilitated by lactic acid bacteria and depends on optimal temperature and pH conditions.

Occurrence in Winemaking

Malolactic fermentation (MLF) is a secondary fermentation process that occurs in many winemaking practices. It involves the conversion of malic acid to lactic acid, reducing acidity and contributing to wine’s overall flavor and aroma.

Factors Influencing Fermentation

Several factors can impact the progress and success of malolactic fermentation in winemaking, including:

- Temperature: MLF typically occurs at temperatures between 15-25°C. Higher temperatures can inhibit the growth of malolactic bacteria and halt the process.

- pH: The ideal pH range for MLF is between 3.0-4.0. Malolactic bacteria thrive in this range, and can struggle at lower pH levels. At pH levels above 4 the unwanted production of acetic acid starts

- Yeasts: The presence of certain yeasts during MLF can result in competition for nutrients between the yeasts and malolactic bacteria, potentially inhibiting MLF.

- Nutrients: Malolactic bacteria require certain nutrients, such as amino acids, to perform MLF effectively. Limited availability of these nutrients can slow down or halt the process.

Detection and Monitoring

Monitoring malolactic fermentation is important in winemaking to ensure its progression and completion. The following methods are commonly used to detect and monitor MLF:

- Tasting: Winemakers can taste the wine periodically to detect changes in acidity and overall flavor.

- pH and TA measurements: Regularly measuring pH and titratable acidity (TA) can provide insights into the progress of MLF, as a decrease in TA typically indicates its completion.

- Paper chromatography: This method allows winemakers to visually track the presence and conversion of malic acid to lactic acid, helping to assess the status of MLF.

- Enzymatic assays: Enzymatic assays can be used to directly measure the concentrations of malic and lactic acids in the wine, offering a more quantitative approach to monitoring MLF.

By considering the influencing factors and employing detection and monitoring methods, winemakers can ensure malolactic fermentation occurs successfully and contributes to the desired characteristics of the final product.

Carbonic Fermentation Versus Malolactic fermentation

In the world of winemaking, two key fermentation processes play a crucial role in shaping the flavor and character of the final product: carbonic fermentation and malolactic fermentation.

What is Carbonic Fermentation

Carbonic fermentation, famously used in the production of Beaujolais Nouveau, is a unique process that takes place within whole grapes without crushing them. This method leads to low tannin levels and fruity flavors that are often associated with young, easy-drinking wines.

Malolactic fermentation

On the other hand, malolactic fermentation involves converting harsh malic acid into smoother lactic acid, resulting in a creamier texture and buttery notes commonly found in Chardonnay and certain red wines.

Flavors generated by carbonic and malolactic fermentation

While carbonic fermentation highlights bright fruit flavors and minimal tannins, malolactic fermentation plays a pivotal role in enhancing the mouthfeel and complexity of wines. The interaction between these two processes can lead to dynamic flavor profiles that add depth and richness to various styles of wine. Winemakers carefully evaluate which type of fermentation to utilize based on their desired characteristics for the final product, allowing for an extensive range of expressions within the world of wine.

Understanding these distinctions can help wine enthusiasts appreciate the meticulous craftsmanship behind every bottle they enjoy.

Malolactic Fermentation in Different Wine Styles

Red Wines

Malolactic fermentation (MLF) is a key process in the production of many red wines, as it softens the wine’s acidity and enhances its complexity. In red wines, MLF typically occurs after primary fermentation, when the wine is racked into the oak barrels, or tanks. Some popular red wines that undergo MLF include Cabernet Sauvignon, Merlot, and Pinot Noir. The process reduces the levels of harsh malic acid in the wine, converting it into rounder, softer lactic acid, which contributes to a smoother mouthfeel.

During MLF, wines can develop secondary aromas and flavors, such as buttery, milky, or toasty notes. These characteristics can complement the fruit-driven primary aromas, creating a more complex and balanced wine. The use of different bacteria strains and fermentation temperatures can influence the final outcome of MLF, providing winemakers with a degree of control over the process.

White Wines

While MLF is common in red wine production, its application in white wines varies depending on the wine style, and desired characteristics. Some full-bodied white wines, such as Chardonnay and Viognier, benefit from MLF, as the process adds richness, creaminess, and complexity to the wine. The classic “buttery” character of some Chardonnays is a prime example of the influence of MLF.

However, not all white wines undergo MLF. For example, winemakers may choose to inhibit MLF in wines like Sauvignon Blanc and Riesling to preserve their natural acidity, maintaining a crisp, fresh, and fruity profile. In these cases, the malic acid is retained, contributing to the wine’s tangy and zesty characteristics.

Rosé Wines

Rosé wines, being lighter and fresher in style, do not commonly undergo MLF. The aim in creating rosé wines is often to retain their bright, lively acidity and delicate fruit flavors. These might be compromised by the softening and textural changes brought about by MLF. However, there are exceptions to this rule, as some winemakers may choose to conduct partial or full MLF in their rosé wines to achieve a specific style or balance.

For instance, certain rosé wines made from grape varieties that are naturally high in acidity, such as Pinot Noir or Cabernet Franc, could benefit from MLF to create a smoother wine with a more approachable character. Ultimately, the decision to carry out MLF in rosé wines depends on the winemaker’s goals and the desired wine profile.

Potential Issues and Solutions

Stuck Fermentation

Stuck fermentation occurs when malolactic bacteria do not completely convert malic acid to lactic acid. This can result in an imbalance in acidity and the development of off-flavors. A few solutions to this issue are:

- Selection of Bacterial Strains: Choose malolactic bacteria strains known for their efficiency and resistance to common inhibitors.

- Proper Nutrition: Ensuring adequate nutrients, such as yeast extract and peptides. They can help the bacteria to thrive and complete the fermentation process.

- Temperature Control: Maintain a consistent and optimal temperature for malolactic fermentation, usually between 15-20°C (59-68°F).

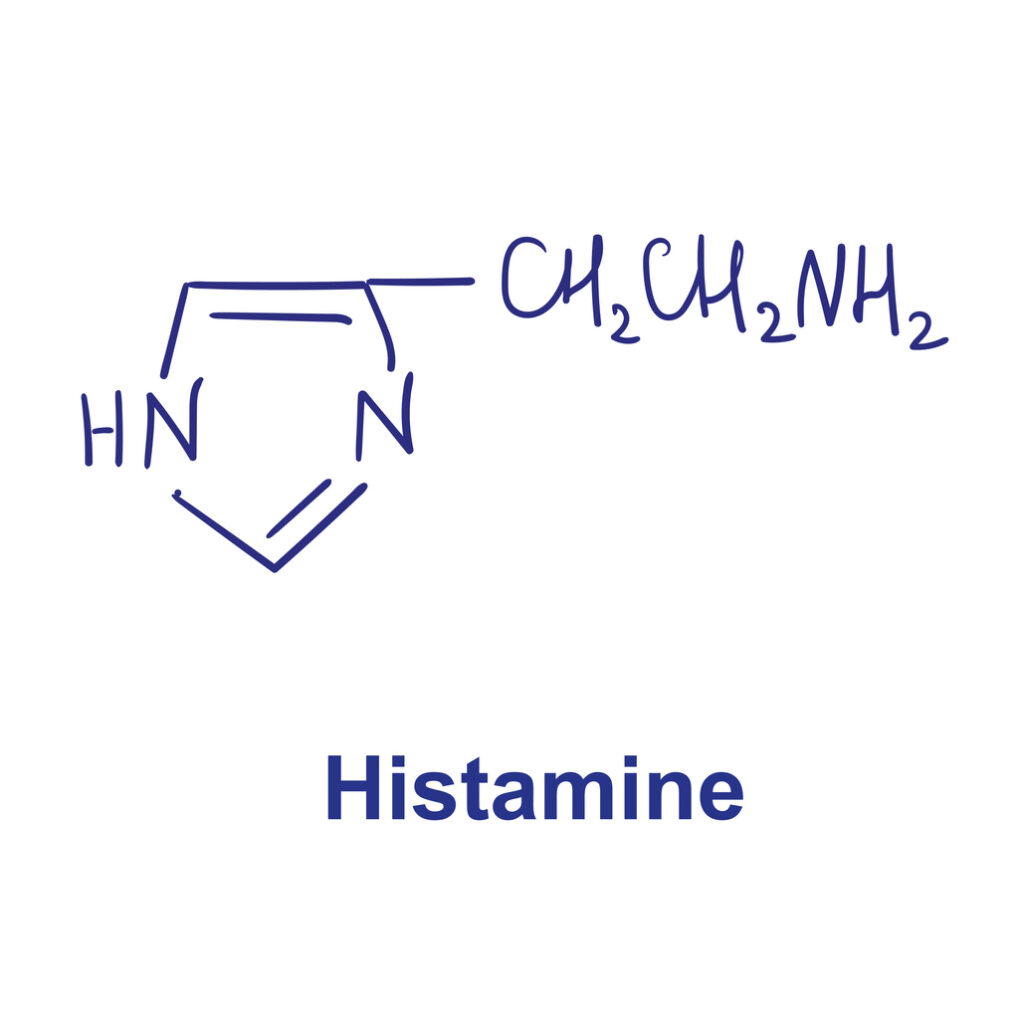

Biogenic Amines Formation

Biogenic amines, such as histamine and tyramine, can form during malolactic fermentation and pose potential health risks. To minimize their formation, consider the following:

- Low Histamine Strains: Utilize bacterial strains that are known to produce low levels of histamine.

- pH Control: Maintain a pH below 3.5 to discourage the growth of bacteria responsible for biogenic amine production.

Aroma and Flavor Changes

Malolactic fermentation can cause undesired aroma and flavor changes, affecting the overall quality of the wine. Implementing the following strategies can help alleviate this issue:

- Partial Malolactic Fermentation: Choose to perform malolactic fermentation on only a portion of the wine. Then blend it with the non-malolactic fermented portion, can help to retain desired freshness and acidity.

- Timing of Fermentation: Initiate malolactic fermentation immediately after primary alcoholic fermentation. This can minimize the risk of the development of off-flavors.

- Proper Storage: Store wine in appropriate conditions (temperature, oxygen exposure) to prevent any unwanted aromatic and flavor changes due to malolactic fermentation.

Innovations and Future Trends

Alternative Methods

One innovation in the field of malolactic fermentation is the utilization of non-Oenococcus bacteria. Examples are Lactobacillus and Pediococcus species, which can have a positive impact on wine flavor and aroma. These alternative methods are being explored- They offer the potential to reduce the production of unwanted compounds like biogenic amines. It also allows for greater control over the complete malolactic fermentation process.

Recent research has also focused on the use of immobilized cells and enzymes to promote malolactic fermentation. This technology seeks to streamline the fermentation process and improve efficiency in winemaking. At the same time the likelihood of spoilage and off-flavors is reduced. Immobilized cells can be used in various forms, such as:

- Beads: Cells are encapsulated in a polymer matrix, usually alginate or κ-carrageenan, which allows for protection from harsh winemaking conditions.

- Bioreactors: Cells are housed in a fixed-bed reactor or fluidized-bed reactor. Here the wine can flow through, promoting an efficient fermentation process.

Genetic Engineering

Genetic engineering has opened new doors for the optimization of malolactic fermentation. This happened particularly through the modification of lactic acid bacteria (LAB) to enhance their performances in wine applications.

For example, engineering LAB with improved tolerance to low pH levels, low temperatures, and high alcohol concentrations can lead to more robust and efficient malolactic fermentations. This reduces the risk of spoilage and improving overall wine quality. Additionally, genetically modified LAB can be fine-tuned to produce specific byproducts that enhance wine’s sensory properties.

Moreover, the development of genetically modified yeast strains capable of carrying out both primary alcoholic fermentation and secondary malolactic fermentation in one step has been proposed. This approach, known as “co-inoculation” or “simultaneous fermentation,” could potentially streamline the winemaking process and improve fermentation efficiency.

Many promising advances have been made in the area of genetic engineering. Regulatory concerns and consumer acceptance of genetically modified organisms in the wine industry still remain challenges. They must be considered in the pursuit of these innovative techniques.

Malolactic Fermentation in Fruit Wines

Malolactic fermentation (MLF) plays a crucial role in shaping the flavor profile of fruit wines. During this process, bacteria convert harsh malic acid into softer lactic acid, resulting in a smoother and more complex character. In fruit wines, MLF can enhance the fruity aromas and create a more balanced acidity, ultimately contributing to a richer and more enjoyable drinking experience.

One fascinating aspect of MLF in fruit wines is its potential to introduce unique flavor nuances. The interaction between the bacterial strains and the specific fruit characteristics can lead to unexpected sensory notes, adding depth and complexity to the wine. Additionally, MLF can also have an impact on mouthfeel, as it softens the acidity and tannins while contributing to a rounder texture. Winemakers who carefully manage this fermentation process can unlock a myriad of possibilities for crafting truly distinctive fruit wines that captivate the senses.

Red wines where Malolactic Fermentation is best avoided?

While malolactic fermentation (MLF) is a common practice in red wine production, there are certain situations where it’s best avoided. For example, lighter-bodied red wines with delicate fruit flavors can be overwhelmed by the buttery, creamy characteristics that MLF can impart. Varieties such as Pinot Noir or Gamay, known for their bright acidity and subtle fruit nuances, may be better off without MLF to preserve their delicate aromas and flavors.

Additionally, some winemakers intentionally avoid malolactic fermentation in certain red wines to maintain a crisp and refreshing profile. Wines like Beaujolais or young Tempranillo often benefit from retaining their natural acidity and fruity freshness without undergoing malolactic fermentation. By skipping MLF, these wines can showcase vibrant fruit character and lively acidity that make them perfect for casual sipping or pairing with a variety of foods. Overall, while MLF is an essential tool in winemaking, there are specific red wine styles where it’s wise for the winemaker, to proceed with caution or skip it altogether to highlight the unique qualities of the grapes used.